ACF-01

MEMIZO

ACF-01

Can be customized

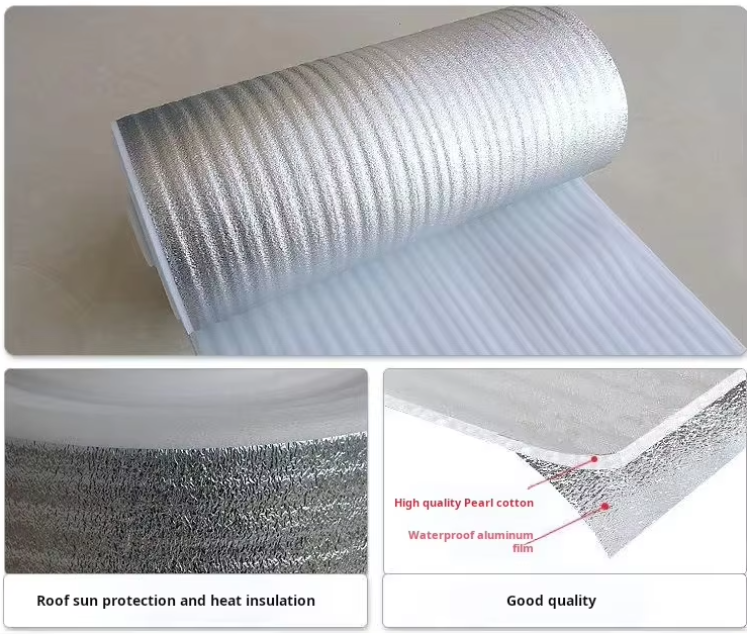

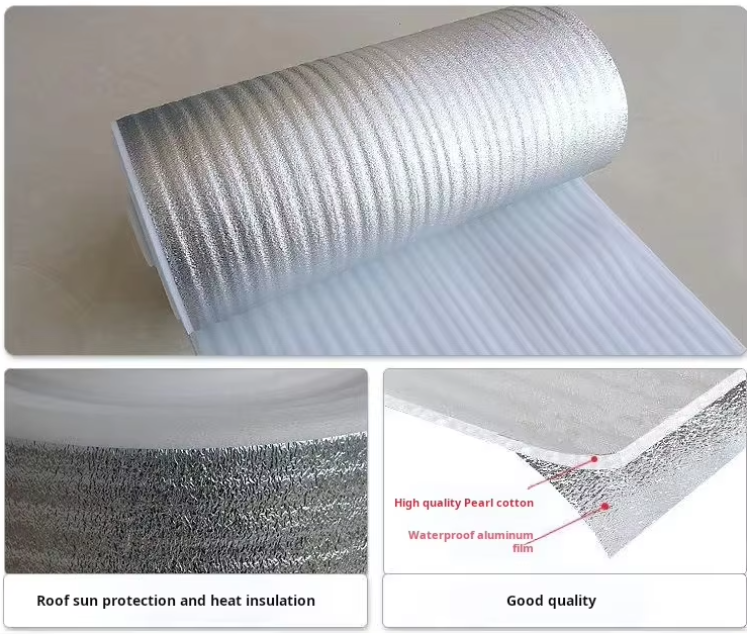

EPE Foam

Easy to install, easy to cut and easy to clean, Strong but lightweight.

Aluminum Coated Film

Insulation, air conditioning, wooden flooring, radiators, HVAC systems, fresh air systems, plumbing systems, etc

| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

Our Aluminum Film Backed EPE Foam is a high-performance material that combines the excellent properties of expanded polyethylene (EPE) foam with the added benefits of an aluminum film backing. This innovative combination makes it an ideal choice for a wide range of applications where thermal insulation, moisture resistance, and mechanical protection are required. The EPE foam itself is known for its lightweight, soft, and resilient nature, providing excellent cushioning and shock absorption. When paired with the aluminum film, which is highly reflective and impervious to water and moisture, the material becomes even more versatile and valuable. Whether it's used in construction, packaging, automotive, or other industries, our Aluminum Film Backed EPE Foam offers a reliable and cost-effective solution.

1. Superior Thermal Insulation: The aluminum film on the EPE foam has a high reflectivity, which effectively reflects radiant heat. This makes the material an excellent thermal insulator, helping to keep the temperature inside a space stable. In construction applications, it can be used as an insulation layer in walls, roofs, and floors to reduce heat transfer and energy consumption. For example, in buildings, it can prevent heat from entering during summer and keep the warmth inside during winter, contributing to energy savings and a more comfortable indoor environment.

2. Excellent Moisture Resistance: The aluminum film acts as a barrier against moisture and water vapor. It prevents moisture from penetrating the EPE foam, ensuring that the foam maintains its performance and integrity over time. This feature is crucial in applications where exposure to moisture is common, such as in packaging for electronic devices or in automotive underbody insulation. By protecting the contents from moisture, it helps to prevent damage and extend the lifespan of the products.

3. Lightweight and Flexible: EPE foam is inherently lightweight, and even with the addition of the aluminum film, the overall material remains relatively light. This makes it easy to handle, install, and transport. Its flexibility also allows it to conform to various shapes and surfaces, making it suitable for applications where a custom fit is required. Whether it's wrapping irregularly shaped objects or installing it in tight spaces, the material can adapt easily.

4. Good Mechanical Protection: The EPE foam provides excellent cushioning and shock absorption, protecting items from impacts and vibrations. When combined with the aluminum film, which adds an extra layer of strength and durability, the material offers enhanced mechanical protection. In packaging applications, it can safeguard delicate products during shipping and handling, reducing the risk of damage.

5. Easy to Install: Our Aluminum Film Backed EPE Foam is designed for easy installation. It can be cut to the desired size and shape using standard cutting tools, and it can be attached to surfaces with adhesives, tapes, or fasteners. This simplicity of installation saves time and labor costs, making it a practical choice for both professional installers and DIY enthusiasts.

6. Versatile Applications: This material has a wide range of applications across different industries. In the construction industry, it can be used for insulation, soundproofing, and waterproofing. In the packaging industry, it provides excellent protection for products during transit. In the automotive industry, it can be used for thermal insulation, noise reduction, and moisture prevention. It can also be used in the manufacturing of furniture, appliances, and other consumer goods.

Q: Is the Aluminum Film Backed EPE Foam flammable?

A: The EPE foam itself has a certain level of flammability, but the aluminum film can act as a barrier to some extent. However, it's important to note that this material is not fireproof. In applications where fire safety is a concern, additional fire-resistant measures may be required, such as using fire-retardant treatments or installing the material in accordance with local fire codes.

Q: Can the material be used in outdoor applications?

A: While the aluminum film provides good protection against moisture and some UV resistance, prolonged exposure to harsh outdoor conditions such as direct sunlight, extreme temperatures, and heavy rain may still cause degradation over time. It can be used outdoors for short-term applications or in protected outdoor areas, but for long-term outdoor use, it's advisable to consider additional protective measures or choose a more suitable outdoor-specific material.

Q: How do I clean the Aluminum Film Backed EPE Foam?

A: Cleaning is relatively simple. You can wipe the aluminum film surface with a damp cloth to remove dirt and dust. Avoid using abrasive cleaners or solvents, as they may damage the aluminum film or the EPE foam. If there are stubborn stains, a mild soap solution can be used, followed by rinsing with clean water and allowing it to dry thoroughly.

Q: Can the material be recycled?

A: Both the EPE foam and the aluminum film can potentially be recycled, but the recycling process may vary depending on local recycling facilities and regulations. It's recommended to check with your local recycling center to determine the best way to recycle this material. In some cases, manufacturers may also have their own recycling programs or guidelines for handling and recycling their products.

| Name | Aluminum Film Backed EPE Foam |

| Structure | VMPET + EPE foam + VMPET |

| Thickness | 2mm,Customization |

| Length /Width(M): | Personalized Customization |

| Water proof | 100 % water-proof |

Our Aluminum Film Backed EPE Foam is a high-performance material that combines the excellent properties of expanded polyethylene (EPE) foam with the added benefits of an aluminum film backing. This innovative combination makes it an ideal choice for a wide range of applications where thermal insulation, moisture resistance, and mechanical protection are required. The EPE foam itself is known for its lightweight, soft, and resilient nature, providing excellent cushioning and shock absorption. When paired with the aluminum film, which is highly reflective and impervious to water and moisture, the material becomes even more versatile and valuable. Whether it's used in construction, packaging, automotive, or other industries, our Aluminum Film Backed EPE Foam offers a reliable and cost-effective solution.

1. Superior Thermal Insulation: The aluminum film on the EPE foam has a high reflectivity, which effectively reflects radiant heat. This makes the material an excellent thermal insulator, helping to keep the temperature inside a space stable. In construction applications, it can be used as an insulation layer in walls, roofs, and floors to reduce heat transfer and energy consumption. For example, in buildings, it can prevent heat from entering during summer and keep the warmth inside during winter, contributing to energy savings and a more comfortable indoor environment.

2. Excellent Moisture Resistance: The aluminum film acts as a barrier against moisture and water vapor. It prevents moisture from penetrating the EPE foam, ensuring that the foam maintains its performance and integrity over time. This feature is crucial in applications where exposure to moisture is common, such as in packaging for electronic devices or in automotive underbody insulation. By protecting the contents from moisture, it helps to prevent damage and extend the lifespan of the products.

3. Lightweight and Flexible: EPE foam is inherently lightweight, and even with the addition of the aluminum film, the overall material remains relatively light. This makes it easy to handle, install, and transport. Its flexibility also allows it to conform to various shapes and surfaces, making it suitable for applications where a custom fit is required. Whether it's wrapping irregularly shaped objects or installing it in tight spaces, the material can adapt easily.

4. Good Mechanical Protection: The EPE foam provides excellent cushioning and shock absorption, protecting items from impacts and vibrations. When combined with the aluminum film, which adds an extra layer of strength and durability, the material offers enhanced mechanical protection. In packaging applications, it can safeguard delicate products during shipping and handling, reducing the risk of damage.

5. Easy to Install: Our Aluminum Film Backed EPE Foam is designed for easy installation. It can be cut to the desired size and shape using standard cutting tools, and it can be attached to surfaces with adhesives, tapes, or fasteners. This simplicity of installation saves time and labor costs, making it a practical choice for both professional installers and DIY enthusiasts.

6. Versatile Applications: This material has a wide range of applications across different industries. In the construction industry, it can be used for insulation, soundproofing, and waterproofing. In the packaging industry, it provides excellent protection for products during transit. In the automotive industry, it can be used for thermal insulation, noise reduction, and moisture prevention. It can also be used in the manufacturing of furniture, appliances, and other consumer goods.

Q: Is the Aluminum Film Backed EPE Foam flammable?

A: The EPE foam itself has a certain level of flammability, but the aluminum film can act as a barrier to some extent. However, it's important to note that this material is not fireproof. In applications where fire safety is a concern, additional fire-resistant measures may be required, such as using fire-retardant treatments or installing the material in accordance with local fire codes.

Q: Can the material be used in outdoor applications?

A: While the aluminum film provides good protection against moisture and some UV resistance, prolonged exposure to harsh outdoor conditions such as direct sunlight, extreme temperatures, and heavy rain may still cause degradation over time. It can be used outdoors for short-term applications or in protected outdoor areas, but for long-term outdoor use, it's advisable to consider additional protective measures or choose a more suitable outdoor-specific material.

Q: How do I clean the Aluminum Film Backed EPE Foam?

A: Cleaning is relatively simple. You can wipe the aluminum film surface with a damp cloth to remove dirt and dust. Avoid using abrasive cleaners or solvents, as they may damage the aluminum film or the EPE foam. If there are stubborn stains, a mild soap solution can be used, followed by rinsing with clean water and allowing it to dry thoroughly.

Q: Can the material be recycled?

A: Both the EPE foam and the aluminum film can potentially be recycled, but the recycling process may vary depending on local recycling facilities and regulations. It's recommended to check with your local recycling center to determine the best way to recycle this material. In some cases, manufacturers may also have their own recycling programs or guidelines for handling and recycling their products.

| Name | Aluminum Film Backed EPE Foam |

| Structure | VMPET + EPE foam + VMPET |

| Thickness | 2mm,Customization |

| Length /Width(M): | Personalized Customization |

| Water proof | 100 % water-proof |